THE BEGINNER’S COURSE

Learn six basic techniques of blacksmithing to get you started and make three items to take home with you.

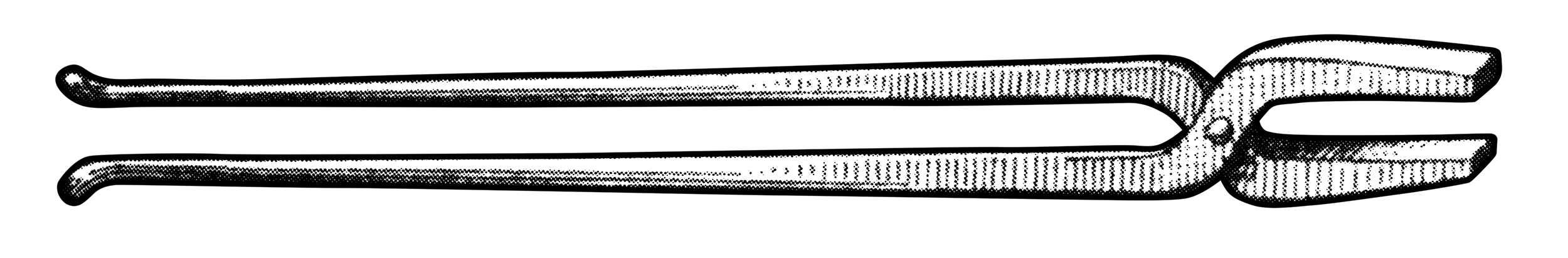

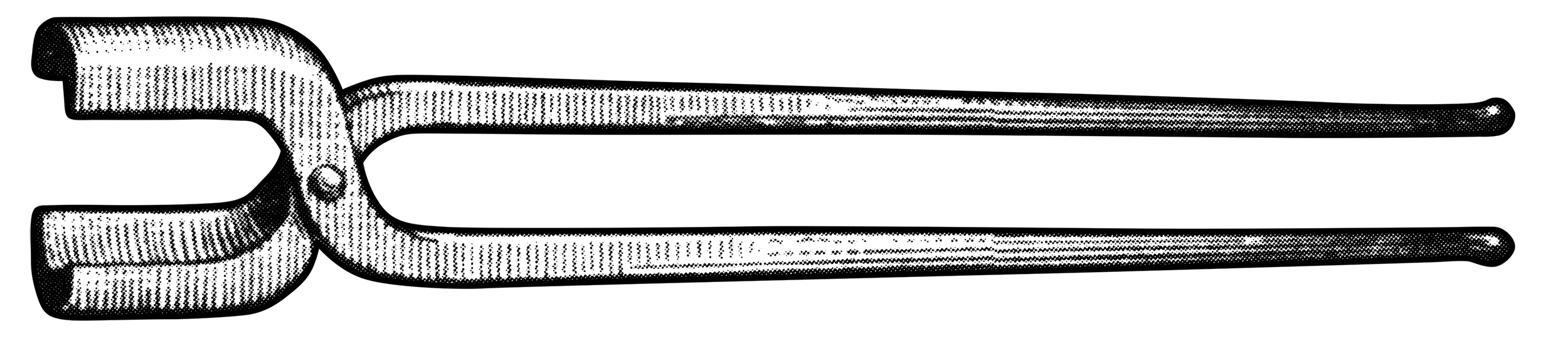

MAKE YOUR OWN TOOLS

Make a blacksmith’s basic toolkit of eight tools and use those tools to make yourself more.

LEAVES & ORGANIC FORMS

Learn more advanced skills to move and shape metal into organic forms with special tools.

SPECIAL SCROLLS

Learn advanced skills in making the more traditional scrolls found in 18th century architectural ironwork.